Lithium-ion battery energy density is high, for safety reasons the general volume will not be designed too large, but a number of single lithium iron phosphate cells through the conductive connectors in series and parallel into a power supply, forming a solar lithium battery module, however, this needs to face the consistency problem.

Inconsistency of solar lithium battery parameters usually include capacity, internal resistance, open-circuit voltage inconsistency, inconsistency of the performance of the battery cell, formed in the production process, will be further aggravated in the process of use, the same battery pack within the cell, the weaker is always weaker and accelerated to become weaker and the degree of dispersion of the parameters between the monomer cell, with the deepening of the degree of aging and become larger.

Related reading: What ls Solar Lithium Battery Consistency?

This article will introduce inconsistent cells when used in series and together, what harm will be brought to the lithium-ion battery PACK and how we should deal with the problem of inconsistent solar lithium batteries.

What Are The Hazards of Inconsistent Solar Lithium Batteries?

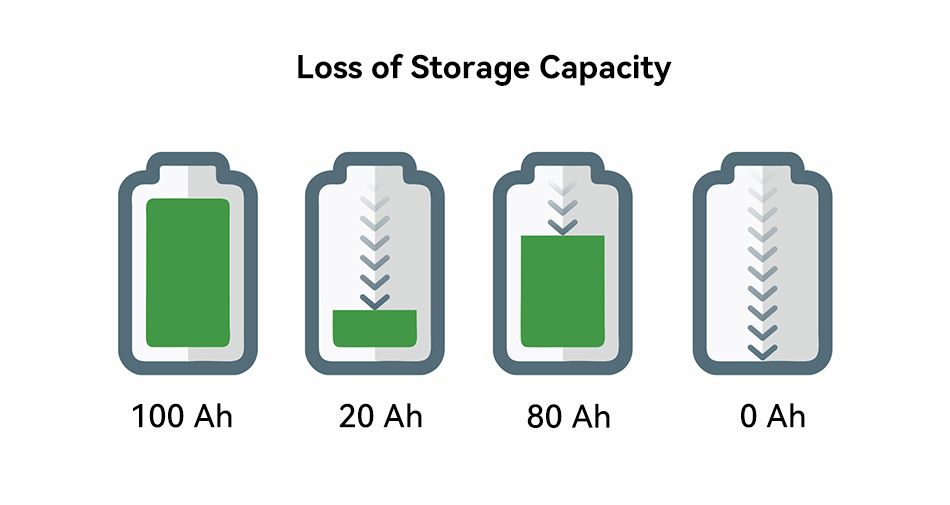

Loss of storage capacity of solar lithium battery pack

In the design of solar lithium battery pack, the overall capacity is in line with the “barrel principle”, the capacity of the worst lithium iron phosphate cell determines the capacity of the entire solar lithium battery pack. In order to prevent overcharging and over-discharging, the battery management system will adopt the following logic:

When discharging: when the lowest single cell voltage reaches the discharge cut-off voltage, the whole battery pack stops discharging;

During charging: when the highest individual voltage touches the charging cut-off voltage, charging is stopped.

In addition, when the smaller capacity battery cell is used in series with the larger capacity battery cell, the smaller capacity battery cell will always be fully discharged, while the larger capacity battery cell will always use part of its capacity, resulting in the capacity of the whole battery pack always having a part of its capacity in an idle state.

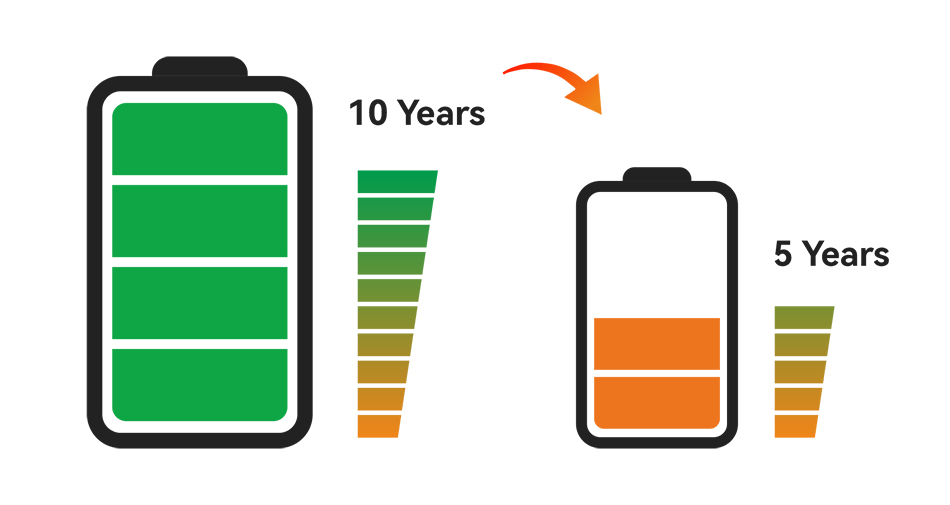

Reduced storage life of solar lithium battery packs

Similarly, the lifespan of a lithium solar battery depends on the lithium iron phosphate cell with the shortest lifespan. It is likely that the cell with the shortest life span is the lithium iron phosphate cell with low capacity. The lower capacity LiFePO4 cell is likely to be the first to reach the end of its life because it is fully charged and discharged every time. When welded as a group of lithium iron phosphate cells end of life, the entire solar lithium battery pack will also follow the end of life.

Increase in internal resistance of solar battery packs

When the same current flows through cells with different internal resistances, the LiFePO4 cell with higher internal resistance generates more heat. This leads to high solar cell temperature, which accelerates the deterioration rate and further increases the internal resistance. A pair of negative feedbacks is formed between internal resistance and temperature rise, which accelerates the deterioration of cells with high internal resistance.

The above three parameters are not completely independent, and deeply aged cells have higher internal resistance and more capacity degradation. Although these parameters affect each other, but separately explain their respective influence direction, help better understand the harm of solar lithium battery inconsistency.

How to Deal With Lithium Solar Battery Inconsistency?

Thermal Management

In response to the problem that lithium iron phosphate cells with inconsistent internal resistance generate different amounts of heat, a thermal management system can be incorporated to regulate the temperature difference across the entire battery pack so that the temperature difference is kept within a small range. In this way, even if the cell that generates more heat still has a high temperature rise, it will not pull away from the other cells, and the deterioration level will not be significantly different. Common thermal management systems include air-cooled and liquid-cooled systems.

Sorting

The purpose of sorting is to separate different parameters and batches of lithium iron phosphate battery cells through selection, even if the same batch of lithium iron phosphate battery cells, but also need to be screened, the parameters of the relative concentration of lithium iron phosphate battery cells in a battery pack, battery Pack. Sorting methods include static sorting and dynamic sorting.

Equalization

Due to the inconsistency of lithium iron phosphate cells, the terminal voltage of some cells will be ahead of other cells and reach the control threshold first, resulting in the capacity of the whole system becoming smaller. The equalization function of the battery management system BMS can solve this problem very well.

When a lithium iron phosphate battery cell is the first to reach the charging cut-off voltage, while the rest of the lithium iron phosphate battery cell voltage lags behind, the BMS will start the charging equalization function, or access to the resistor, to discharge part of the power of the high-voltage lithium iron phosphate battery cell, or transfer the energy away to the low-voltage lithium iron phosphate battery cell up. In this way, the charging cut-off condition is lifted, the charging process starts again, and the battery pack can be charged with more power.

Post time: Sep-03-2024