By 2024, the booming global energy storage market has led to the gradual recognition of the critical value of battery energy storage systems in various markets, especially in the solar energy market, which has gradually become an important part of the grid. Due to the intermittent nature of solar energy, its supply is unstable, and battery energy storage systems are able to provide frequency regulation, thereby effectively balancing the operation of the grid. Going forward, energy storage devices will play an even more important role in providing peak capacity and deferring the need for costly investments in distribution, transmission, and generation facilities.

The cost of solar and battery energy storage systems has fallen dramatically over the past decade. In many markets, renewable energy applications are gradually undermining the competitiveness of traditional fossil and nuclear power generation. Whereas it was once widely believed that renewable energy generation was too costly, today the cost of certain fossil energy sources is much higher than the cost of renewable energy generation.

Additionally, a combination of solar + storage facilities can provide power to the grid, replacing the role of natural gas-fired power plants. With investment costs for solar power facilities significantly reduced and no fuel costs incurred throughout their lifecycle, the combination is already providing energy at a lower cost than traditional energy sources. When solar power facilities are combined with battery storage systems, their power can be used for specific periods of time, and the fast response time of the batteries allows their projects to respond flexibly to the needs of both the capacity market and the ancillary services market.

Currently, lithium-ion batteries based on lithium iron phosphate (LiFePO4) technology dominate the energy storage market. These batteries are widely used due to their high safety, long cycle life and stable thermal performance. Although the energy density of lithium iron phosphate batteries is slightly lower than that of other types of lithium batteries, they have still made significant progress by optimising production processes, improving manufacturing efficiency and reducing costs. It is expected that by 2030, the price of lithium iron phosphate batteries will further decrease, while their competitiveness in the energy storage market will continue to increase.

With the rapid growth in demand for electric vehicles, residential energy storage system, C&I energy stroage system and large-scale energy storage systems, the advantages of Li-FePO4 batteries in terms of cost, lifetime and safety make them a reliable option. While its energy density targets may not be as significant as those of other chemical batteries, its advantages in safety and longevity give it a place in application scenarios that require long-term reliability.

Factors to Consider When Deploying Battery Energy Storage Equipment

There are many factors to consider when deploying energy storage equipment. The power and duration of the battery energy storage system depends on its purpose in the project. The purpose of the project is determined by its economic value. Its economic value depends on the market in which the energy storage system participates. This market ultimately determines how the battery will distribute energy, charge or discharge, and how long it will last. So the power and duration of the battery not only determines the investment cost of the energy storage system, but also the operational life.

The process of charging and discharging a battery energy storage system will be profitable in some markets. In other cases, only the cost of charging is required, and the cost of charging is the cost of conducting the energy storage business. The amount and rate of charging is not the same as the amount of discharging.

For example, in grid-scale solar+battery energy storage installations, or in client-side storage system applications that use solar energy, the battery storage system uses power from the solar generating facility in order to qualify for investment tax credits (ITCs). For example, there are nuances to the concept of pay-to-charge for energy storage systems in Regional Transmission Organisations (RTOs). In the investment tax credit (ITC) example, the battery storage system increases the equity value of the project, thereby increasing the owner’s internal rate of return. In the PJM example, the battery storage system pays for charging and discharging, so its payback compensation is proportional to its electrical throughput.

It seems counterintuitive to say that the power and duration of a battery determine its lifetime. A number of factors such as power, duration, and lifetime make battery storage technologies different from other energy technologies. At the heart of a battery energy storage system is the battery. Like solar cells, their materials degrade over time, reducing performance. Solar cells lose power output and efficiency, while battery degradation results in the loss of energy storage capacity. While solar systems can last 20-25 years, battery storage systems typically last only 10 to 15 years.

Replacement and replacement costs should be considered for any project. The potential for replacement depends on the throughput of the project and the conditions associated with its operation.

The four main factors that lead to a decline in battery performance are?

- Battery operating temperature

- Battery current

- Average battery state of charge (SOC)

- The ‘oscillation’ of the average battery state of charge (SOC), i.e., the interval of the average battery state of charge (SOC) that the battery is in most of the time. The third and fourth factors are related.

There are two strategies for managing battery life in the project. The first strategy is to reduce the size of the battery if the project is supported by revenue and to reduce the planned future replacement cost. In many markets, planned revenues can support future replacement costs. In general, future cost reductions in components need to be considered when estimating future replacement costs, which is consistent with market experience over the past 10 years. The second strategy is to increase the size of the battery in order to minimise its total current (or C-rate, simply defined as charging or discharging per hour) by implementing parallel cells. Lower charging and discharging currents tend to produce lower temperatures since the battery generates heat during charging and discharging. If there is excess energy in the battery storage system and less energy is used, the amount of charging and discharging of the battery will be reduced and its life extended.

Battery charge/discharge is a key term. The automotive industry typically uses ‘cycles’ as a measure of battery life. In stationary energy storage applications, batteries are more likely to be partially cycled, meaning they may be partially charged or partially discharged, with each charge and discharge being insufficient.

Available Battery Energy. Energy storage system applications may cycle less than once per day and, depending on the market application, may exceed this metric. Therefore, staff should determine battery life by assessing battery throughput.

Energy Storage Device Life and Verification

Energy storage device testing consists of two main areas. First, battery cell testing is critical to assessing the life of a battery energy storage system. Battery cell testing reveals the strengths and weaknesses of the battery cells and helps operators understand how the batteries should be integrated into the energy storage system and whether this integration is appropriate.

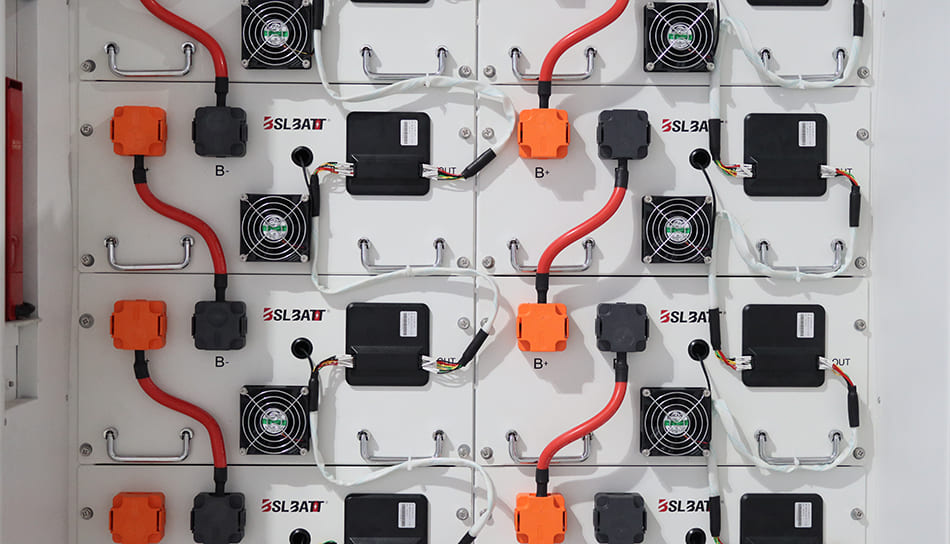

Series and parallel configurations of battery cells help to understand how a battery system works and how it is designed. Battery cells connected in series allow for stacking of battery voltages, which means that the system voltage of a battery system with multiple series-connected battery cells is equal to the individual battery cell voltage multiplied by the number of cells. Series-connected battery architectures offer cost advantages, but also have some disadvantages. When batteries are connected in series, the individual cells draw the same current as the battery pack. For example, if one cell has a maximum voltage of 1V and a maximum current of 1A, then 10 cells in series have a maximum voltage of 10V, but they still have a maximum current of 1A, for a total power of 10V * 1A = 10W. When connected in series, the battery system faces a challenge of voltage monitoring. Voltage monitoring can be performed on series-connected battery packs to reduce costs, but it is difficult to detect damage or capacity degradation of individual cells.

On the other hand, parallel batteries allow for current stacking, which means that the voltage of the parallel battery pack is equal to the individual cell voltage and the system current is equal to the individual cell current multiplied by the number of cells in parallel. For example, if the same 1V, 1A battery is used, two batteries can be connected in parallel, which will cut the current in half, and then 10 pairs of parallel batteries can be connected in series to achieve 10V at 1V voltage and 1A current, but this is more common in a parallel configuration.

This difference between series and parallel methods of battery connection is important when considering battery capacity guarantees or warranty policies. The following factors flow down through the hierarchy and ultimately affect battery life: market features ➜ charging/discharging behaviour ➜ system limitations ➜ battery series and parallel architecture. Therefore, battery nameplate capacity is not an indication that overbuilding may exist in the battery storage system. The presence of overbuilding is important for the battery warranty, as it determines the battery current and temperature (cell dwell temperature in the SOC range), while daily operation will determine the battery lifetime.

System testing is an adjunct to battery cell testing and is often more applicable to project requirements that demonstrate proper operation of the battery system.

In order to fulfil a contract, energy storage battery manufacturers typically develop factory or field commissioning test protocols to verify system and subsystem functionality, but may not address the risk of battery system performance exceeding battery life. A common discussion about field commissioning is capacity test conditions and whether they are relevant to the battery system application.

Importance of Battery Testing

After DNV GL has tested a battery, the data is incorporated into an annual battery performance scorecard, which provides independent data for battery system purchasers. The scorecard shows how the battery responds to four application conditions: temperature, current, mean state of charge (SOC) and mean state of charge (SOC) fluctuations.

The test compares battery performance to its series-parallel configuration, system limitations, market charging/discharging behaviour and market functionality. This unique service independently verifies that battery manufacturers are responsible and correctly assess their warranties so that battery system owners can make an informed assessment of their exposure to technical risk.

Energy Storage Equipment Supplier Selection

In order to realise the battery storage vision, supplier selection is critical – so working with trusted technical experts who understand all aspects of utility-scale challenges and opportunities is the best recipe for project success. Selecting a battery storage system supplier should ensure that the system meets international certification standards. For example, battery storage systems have been tested in accordance with UL9450A and test reports are available for review. Any other location-specific requirements, such as additional fire detection and protection or ventilation, may not be included in the manufacturer’s base product and will need to be labelled as a required add-on.

In summary, utility-scale energy storage devices can be used to provide electrical energy storage and support point-of-load, peak demand, and intermittent power solutions. These systems are used in many areas where fossil fuel systems and/or traditional upgrades are considered inefficient, impractical or costly. Many factors can impact the successful development of such projects and their financial viability.

It is important to work with a reliable battery storage manufacturer. BSLBATT Energy is a market-leading provider of intelligent battery storage solutions, designing, manufacturing and delivering advanced engineering solutions for specialist applications. The company’s vision is focused on helping customers solve the unique energy issues that affect their business, and BSLBATT’s expertise can provide fully customised solutions to meet customer objectives.

Post time: Aug-28-2024